Have you ever noticed the miniature packs in medication bottles and other products and wondered what they were for? They contain essential drying agents that maintain quality and extend shelf life.

Introducing desiccant packs to automated packaging requires a strategic plan to ensure maximum efficiency.

What Are Desiccant Packs?

Even trace amounts of moisture can damage sensitive items. Desiccant packs prevent harm by attracting water with various porous substances.

- Molecular sieves: Excellent at collecting moisture in high- or low-humidity environments.

- Calcium chloride: The same salt used to de-ice sidewalks and roads in winter.

- Silica gel: A standard desiccant pack material that works well in moderately humid environments. The gel includes numerous pores to absorb moisture.

- Clay: A cheaper material that excels in moderately humid environments, but may be less effective in higher humidity.

The packaging containing the substance is typically kraft paper or synthetic polyethylene fiber material.

Applications for Moisture Control Automated Packaging

Desiccant packs are highly adaptable, and several industries rely on them.

Vitamins and Supplements

Supplements include powder-based products, pills and herbal capsules, which are often sensitive to moisture, light and heat. Exposure to humidity may make active ingredients less effective.

Food and Beverage

Particularly beneficial for products such as coffee and dried fruit, desiccant packs prevent mold growth and keep food from going soggy. Introducing desiccant packs maintains customer satisfaction by consistently delivering fresh food and drink products.

Electronics and Automotive

Exposure to moisture is a concern for electronic items and automotive parts. Water is especially detrimental to metal, as it can cause corrosion. Short circuits are another concern that may result in faulty electrical products. Use desiccant packs to limit reputational damage and prevent safety issues.

Medical and Pharmaceutical

Prescription powders, capsules and pills can degrade when exposed to moisture. If you don't use desiccant packs, you may risk making medicines less effective and harming patients.

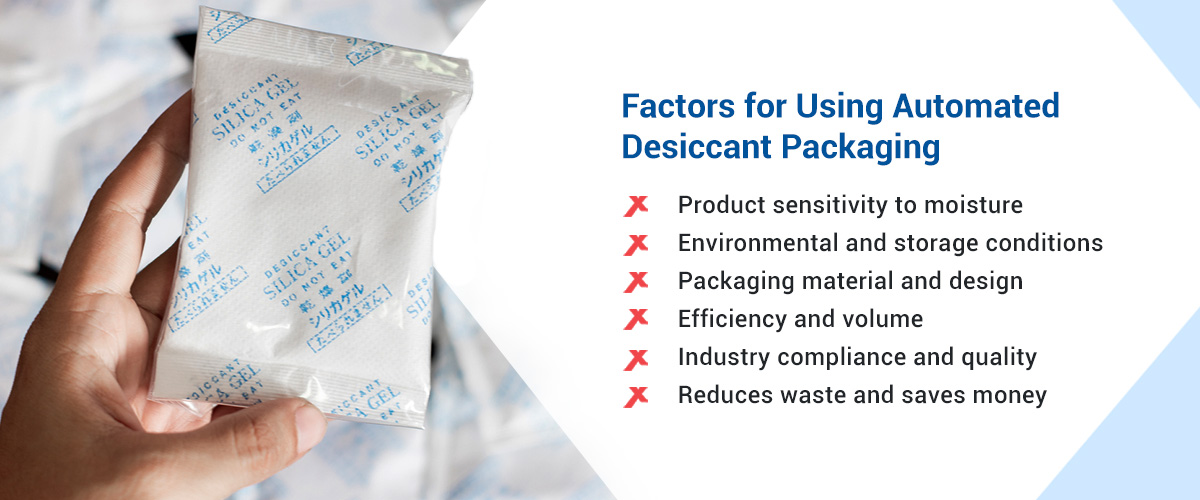

Factors for Using Automated Desiccant Packaging

Desiccant packs are a viable option for automated packaging solutions. The packs are suitable for various machine types for quick dispensing and accuracy. The following factors outline how and when to use desiccant packs in automated packaging.

- Product sensitivity to moisture: Even trace amounts of moisture or humidity can affect product quality. Automated packaging solutions give each desiccant pack the correct amount of substance for absorbing moisture.

- Environmental and storage conditions: Conditions between the packing station and shipping vehicles will fluctuate. Integrating an automated desiccant inserter gives you the flexibility to adjust settings to ensure complete protection.

- Packaging material and design: Package design is critical for many products. Automated inserters accurately place desiccant packs and maintain consistent speeds.

- Efficiency and volume: Production lines move quickly. In these environments, manually placing the packs is unproductive and may cause human error. Automation meets high quality and productivity demands.

- Industry compliance and quality: Industries such as medical and food must follow stringent safety regulations. Automated packaging solutions meet these requirements, ensuring compliance with standards.

- Reduces waste and saves money: Manually dispensing desiccant may lead to inaccuracies. Setting machines up to dispense the correct amount of desiccant for each pack saves money on materials and limits waste.

Integrating Desiccant Packs in Automated Packaging

The ideal integration method depends on the type of packaging line, the desiccant pack format and your productivity requirements. Explore the automated humidity control packaging types below for effective integration.

Flexible Packaging Lines

The automated bagging system series is particularly beneficial for dry goods moisture protection. The ABS solution can open, fill and seal approximately 20 packages per minute and is a user-friendly system with customizable features to meet unique requirements.

Rigid Container Lines

With packaging such as rigid desiccant canisters, using solutions primarily for bottles and cans is an effective solution for multipack formation and high-speed automatic shrink bundling. Rigid container lines, inserters or chutes can drop the desiccant canisters into containers during the packaging stage.

Continuous Strip Systems

Continuous band sealing is beneficial for desiccant packaging. Band sealers work by checking speed, pressure and temperature during production. With simple touch controls, the systems are easy to manage and prevent human error. Continuous strip systems also deliver airtight seals, which are crucial for desiccant packs.

ROI Considerations for Packaging Line Desiccant Insertion

Before implementing a fully automated packaging solution, weigh the long-term benefits against your initial investment to determine your return. Though automated packaging significantly impacts productivity, your analysis should consider demand and quality requirements.

- Initial cost analysis: Your first consideration is the up-front costs, which include the potential integration with existing technology, the inserter and possible customized packaging solution needs for your operation. Initial expenses are justifiable to replace workers and reduce human errors, especially if you run a high-volume production line.

- Weighing costs and benefits: Depending on your operation, the costs of accommodating high-volume desiccant pack jobs may be reasonable. Setting specific criteria to manage moisture control and limiting the amount of material waste also helps with cost savings.

- ROI of automated desiccant packaging: The best way to calculate your potential is to add up the annual savings on waste, labor and better customer satisfaction. Eliminating production issues will result in higher quality. Larger businesses will likely experience a higher return on investment due to the speed and product requirements.

Choose Plexpack for Your Automated Packaging Needs

Desiccant packs' benefits make them suitable for a wide range of packages. Partner with Plexpack for custom solutions that exceed your expectations. From electronics to pharmaceutical and food products, our team has over 50 years of experience providing businesses with effective packaging to maintain excellent quality.

Complete our contact form to discuss all available options.