For producers of perishable goods, the right packaging technology directly impacts shelf life, product integrity and profitability. Consumers expect high-quality items, and packaging is often what determines it. Modified atmosphere packaging (MAP) offers a powerful solution, yet it's crucial to choose the right sealing technology. This guide directly compares two primary MAP technologies — systems using gas flush with compression belts and those using vacuum sealing.

Both methods can ensure an optimal internal packing environment, but they use different approaches and have their own benefits and considerations. Understanding their differences can help you choose a system that aligns with your specific product needs, operations and business goals.

MAP Decision Factors for Your Product Line

Modified atmosphere packaging (MAP) is a method that extends the shelf life of perishable goods by altering the gas composition within the package. The approach involves replacing the ambient air with a precisely controlled mixture of gases, often oxygen, carbon dioxide and nitrogen. This slows down spoilage that can occur, like oxidation and microbial growth.

However, to successfully implement MAP, you need a strategic approach. Consider the following factors to choose the most effective and efficient MAP solution for your product line:

- Product characteristics: It's critical to first assess the characteristics of the product you're working with. Each product has unique properties that determine the type of packaging it needs. For example, consider sensitivity to pressure, since delicate items, such as fresh berries or baked goods, could easily be damaged by a vacuum. Texture is also critical — will a vacuum crush or deform the product? Lastly, consider moisture content and respiration rate, as these influence the ideal gas mix and the package's ability to maintain that pressure. For example, leafy greens have a high respiration rate and will need a different MAP strategy than a dense food like a block of cheese.

- Business objectives: Next, consider your exact business objectives. What is the desired shelf life for your product? A longer shelf life may require a stronger MAP solution, such as higher-barrier films or more complex gas mixtures. The distribution environment also plays an important role — products destined for long-haul shipments across continents will likely have different requirements than those distributed locally. Further, consider how you want the product to look on the shelf. Will a tightly vacuum-sealed package be right for the product's image, or does it need a more natural, uncompressed appearance?

- Operational constraints: Evaluate your operational constraints, like budget, plant footprint and the skill level of your line operators. Budget limitations can affect the type of equipment and materials you can acquire, and some MAP systems can require more space than others. At the same time, complex machinery may demand more extensive training, while simpler systems might be more easily integrated with your existing staff.

Balancing these factors will ensure that your chosen MAP system is effective, economically viable and operationally sustainable.

Gas Flush With Compression Belts vs. Vacuum Packaging

There are two main mechanical approaches behind modified atmosphere packaging. These include gas flushing with compression belts and traditional vacuum packaging. While both aim to create an optimal internal package environment, their functions and applications differ significantly. Here, we'll discuss these differences, how each system operates and the type of products and scenarios where you might choose one over the other.

How Gas Flush Systems Work

Gas flush sealing is a MAP method that keeps perishable products fresh by displacing the ambient air within a package with a precisely controlled mixture of gases. It does this without creating a vacuum that could damage delicate products. Compression belts are often used at the core of this process, which follows these steps:

- Pressing: As the package moves through the sealing station, the belts gently but firmly press down on the package, controlling the headspace above the product.

- Expelling existing air: The controlled compression helps expel the existing air, creating an ideal environment in which to introduce the desired gas mixture.

- Injecting inert gas: The inert gas or gas blend is injected into the package to flush out residual oxygen.

- Sealing: The compression belts maintain this controlled headspace as the package is sealed, ensuring a high-quality, consistent seal that locks in the modified atmosphere.

Gas flush packaging works especially well for products that are sensitive to pressure or could be easily deformed. Delicate items like leafy greens, baked goods, fresh pasta, and even some prepared meals can benefit from gas flushing packaging since it preserves their structure and presentation. Products with irregular shapes or requiring specific airflow around them also thrive, since they avoid crushing or compacting.

With the gentle nature of gas flushing combined with precise control from the compression belts, this is an ideal method for keeping products fresh and extending their shelf life without affecting their presentation.

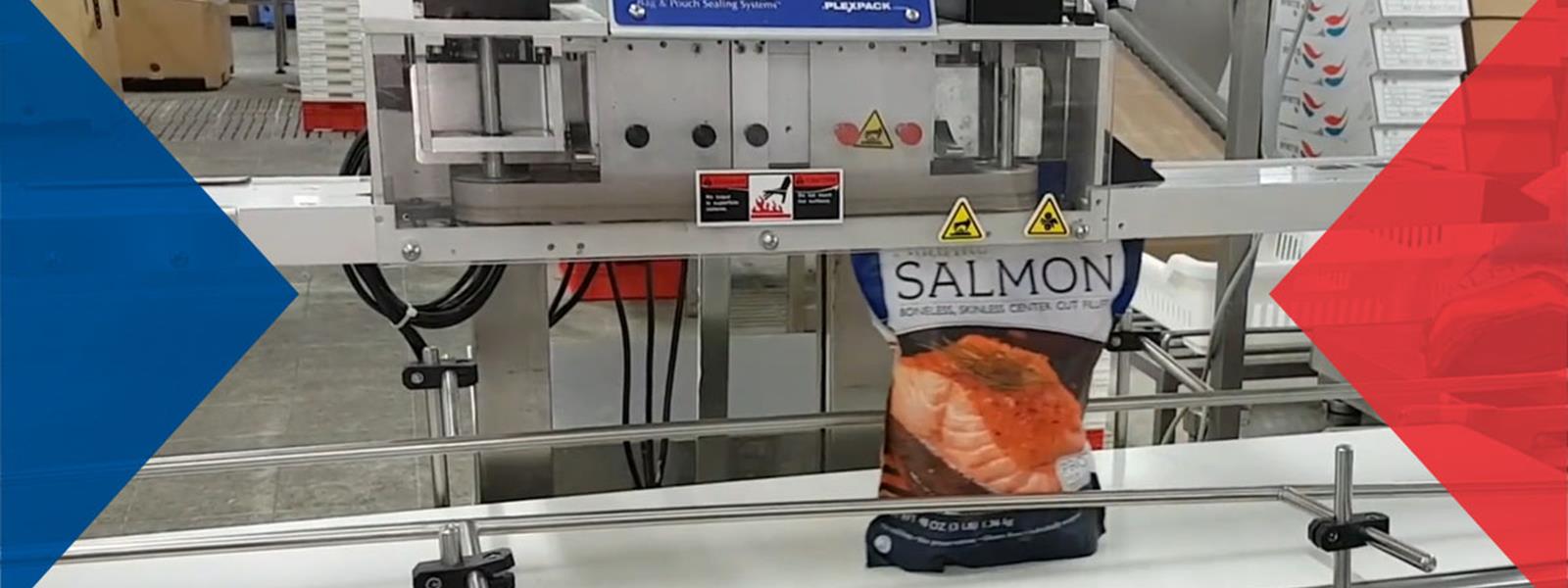

How Vacuum Packaging Systems Work

Traditional vacuum packaging for food products focuses on removing air from the package using a pump. This creates a vacuum that eliminates oxygen. After removing oxygen, a sealer heats the edges of the package to keep air from re-entering it. Many producers use this method to prolong the shelf life of food, as drastically reducing oxygen inhibits bacterial growth and slows down oxidative spoilage.

This method is especially beneficial for dense products, those that need a high barrier from oxygen, or food intended for long-haul distribution, helping to preserve them for an extended period. For instance, large cuts of meat, poultry and hard cheeses can all benefit from vacuum packaging. The compression can reduce the package's volume and prevent freezer burn. However, the process can also crush delicate foods, making it best-suited for dense products.

Staged and Hybrid MAP Approaches

More advanced MAP strategies might employ a combination of gas flushing and vacuum packaging techniques to achieve more specific results. For example, a common hybrid method involves initiating a partial vacuum to remove a significant portion of the ambient air, followed immediately by a gas flush. This method allows for more efficient and precise control over the final gas composition in the package, as less residual oxygen needs to be displaced by the introduced gas mixture.

A hybrid approach can benefit products that require low oxygen levels for extended shelf life, but are too delicate for a full vacuum. For example, some baked goods or prepared meals could benefit from a partial vacuum to quickly reduce oxygen in addition to a gentle gas flush to create a more protective atmosphere without compromising the product.

Assuring Product and Sealing Integrity

An effective MAP system requires a strong final package seal. A compromised seal can lead to premature spoilage, product returns and damage to your brand reputation. A secure seal is a science that relies on a precise interplay of temperature, pressure, time and material compatibility:

- Temperature: First, the sealing bars must reach and maintain the right temperature to melt the sealant layers of the packaging film.

- Pressure: While the sealing bars are reaching the correct temperature, consistent pressure must be applied to fuse the sealant layers together. The pressure must be maintained for a sufficient amount of time to allow the molten material to cool and solidify into a strong bond.

- Material compatibility: The packaging material itself must be compatible with the sealing technology and the product. This will ensure it can withstand the sealing process and maintain its barrier properties throughout the product's shelf life.

Quality Assurance and Leak Detection

Beyond the sealing process, you need a quality assurance and leak detection method for continuous verification.

Technologies like vacuum decay testing can find microscopic leaks by subjecting the sealed packages to a vacuum and monitoring for pressure changes. At the same time, vision systems can inspect the seal's appearance, looking for wrinkles, contamination in the seal area or misaligned films that could compromise the product's integrity.

These automated systems will provide you with real-time feedback, allowing you to make quick adjustments and prevent defective packages from entering the market.

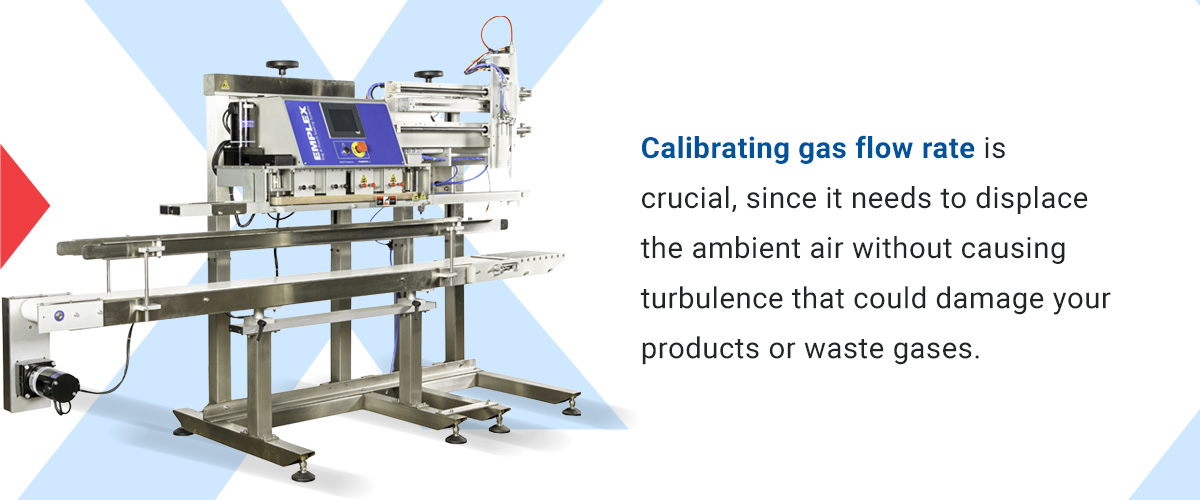

Optimizing Gas Flush Systems

For gas flush packaging systems, you'll need to optimize the process to protect the product's integrity and gas efficiency. Calibrating gas flow rate is crucial, since it needs to displace the ambient air without causing turbulence that could damage your products or waste gases. Dwell time, or the period during which gas is introduced, must be sufficient to achieve the desired residual oxygen level. Too short and the oxygen stays, but too long and gas is wasted.

Managing turbulence is also key — a smooth and laminar flow will lead to faster gas exchange while preventing the product from being disturbed. By carefully controlling these parameters, you can consistently achieve and maintain the intended modified atmosphere, protecting the quality of your products and extending their shelf life.

Balancing Throughput, Shelf Life and Presentation

For any production manager, deciding between compression belt gas flush and vacuum packing systems will come down to three key performance indicators — throughput, desired shelf life and the final presentation of your product. Your goal should always be to strike a balance between them for optimal efficiency and market appeal.

Throughput

Throughput is an especially crucial factor in high-speed environments. Compression belt gas flush systems, especially continuous band sealers, usually have faster cycle times than traditional chamber vacuum machines. In a gas flush setup, packages move continuously through the sealing process, with gas injection and sealing happening in rapid succession.

While inline vacuum machines can be faster than chamber models, the time needed to pull a deep vacuum in each package or chamber can still be a limiting factor when compared to the continuous flow of a gas flush system. The difference in cycle time can affect the overall production volume, making gas flush packaging preferable if your operation demands high output.

Shelf Life

The main goal of modified atmosphere packaging, achieving the desired shelf life, is largely dictated by the gas mix strategies you use. Different product categories will need specific ratios of gases, like carbon dioxide (CO2), nitrogen (N2) and oxygen (O2), to effectively keep food fresh and deter spoilage. For example, red meats usually need a higher oxygen content to keep their vibrant color, while baked goods or prepared meals benefit from low oxygen and high nitrogen to keep mold from growing.

Both gas flush and vacuum systems can introduce the right gas mixture, but the efficiency of gas exchange and the ability to maintain precise concentrations can differ. Gas flush systems are ideal for rapidly introducing a specific atmosphere, while vacuum systems and hybrid systems can achieve extremely low residual oxygen levels before the gas is introduced.

Presentation

Aesthetics are crucial, as they influence how customers view your products and your overall brand identity. The packaging method you use vastly affects the product's appearance. While vacuum packaging can create a tight and form-fitting appearance, it can sometimes cause the film to wrinkle and will be more obvious in products with irregular shapes. While you might desire this for products like large cuts of meat, it can be less appealing for others. Product visibility is also affected by the packaging method, since a tight seal can sometimes obscure details.

In contrast, gas flush systems preserve the products' natural shape and headspace, offering a more relaxed, pillow-like package that can enhance the product's overall appearance while keeping it from being crushed. This is important for branding and integrating your labels, as it offers a smooth and wrinkle-free surface that's perfect for displays.

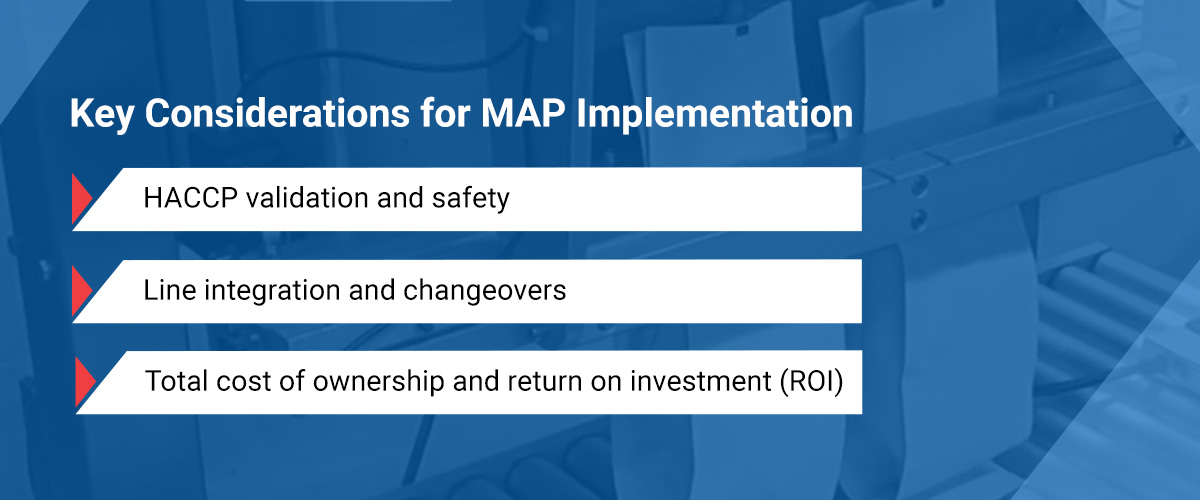

Key Considerations for MAP Implementation

To choose the right MAP system for your facility, you'll need to consider factors like regulatory compliance, operational flow and financial viability. Your final choice should result in a high-quality product with a longer shelf life, while seamlessly integrating into your workflow and yielding a strong return on investment.

- HACCP validation and safety: Food safety is critical, and for MAP, this means hazard analysis and critical control points (HACCP) validation. It involves finding critical control points within your MAP process, such as precise gas composition and robust seal parameters. Using these validation protocols and continuously verifying them can help you meet compliance, keep products safe and achieve audit readiness.

- Line integration and changeovers: Your modified atmosphere packaging machine must be able to integrate easily with upstream and downstream equipment like weighers, fillers, conveyors, checkweighers, metal detectors and case packers without disrupting your production. You also need to be able to perform fast changeovers. This may involve making tool-less adjustments for various package sizes or film types, or using recipe recall functions on the machine to load preset parameters for different products.

- Total cost of ownership and return on investment (ROI): The upfront cost of the machine is just one financial factor to consider when choosing your MAP system. You should also consider the packaging materials you use, gas consumption, labor costs and ongoing maintenance. To determine ROI, consider how a longer shelf life can directly translate to less food waste, a huge cost-saving benefit. Further, being able to extend your distribution range can open up new markets and revenue streams. Enhancing the product's quality and presentation from the MAP can also command premium pricing, directly impacting profitability.

Partner With Plexpack for Your MAP System

Ultimately, the right sealing technology can ensure optimal preservation and presentation of your valuable goods, helping you stay ahead in a competitive industry. To navigate the complexities of modified atmosphere packaging, you need expertise from a partner you can trust. Turn to Plexpack for made-to-order, customizable solutions tailored to your unique product and operational needs. We have helped thousands of companies worldwide choose the best product packaging option. We offer efficient and high-quality gas flush vacuum seal machines that can streamline your packaging processes.

Beyond installation, Plexpack's commitment extends to long-term uptime through our reliable aftermarket support, Plexpack Certain Assist. Don't leave your MAP success to chance. Contact us to learn about our innovative products. We will work with you to find the best product choices that fit your budget and application.